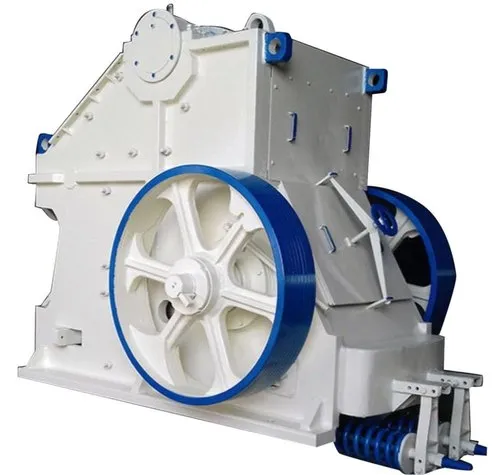

Double Roller Crusher: Durable & Efficient Crushing

18 Aug 2025 | Admin

Crushers are among the most essential machines in the mining, cement, and aggregate industries. They play a vital role in breaking down raw materials into smaller, more manageable sizes for further processing. Among the many crusher types available, the double roller crusher has gained significant attention for its durability, efficiency, and suitability for fine crushing applications.

What is a Double Roller Crusher?

A double roller crusher is a compression crusher that uses two parallel rollers to crush materials. The rollers rotate in opposite directions, pulling material between them and breaking it into smaller pieces. This makes them highly suitable for fine and medium crushing applications in cement, mining, coal, and chemical industries.

Working Principle

The operation of a double roller crusher is straightforward yet effective:

- Feeding: Raw material enters the gap between the rollers.

- Compression: Rollers rotate in opposite directions, applying compressive force.

- Size Reduction: Material is crushed and discharged at a controlled size.

- Adjustability: Gap between rollers can be adjusted to control product size.

Key Features

- Durable Construction: Built with heavy-duty, wear-resistant materials.

- High Crushing Ratio: Reduces large feed into fine particles in one pass.

- Energy Efficient: Uses compressive force, lowering energy consumption.

- Adjustable Output: Roller gap can be controlled to meet product size needs.

- Low Dust & Noise: Generates less dust and noise compared to impact crushers.

Advantages of Double Roller Crushers

- Efficiency: Produces uniform particle sizes for downstream processes.

- Versatility: Handles coal, limestone, gypsum, slag, clay, and ores.

- Cost-Effective: Low wear parts and low operational costs.

- Environmentally Friendly: Reduced dust and noise pollution.

Applications

- Mining Industry – crushing ores and slag

- Cement Industry – crushing limestone, clay, and clinker

- Coal Handling – crushing coal for power plants

- Chemical Industry – processing fertilizers and salts

- Construction Materials – aggregates and sand production

Comparison with Other Crushers

| Feature | Double Roller Crusher | Jaw Crusher | Impact Crusher |

|---|---|---|---|

| Mechanism | Compression (rollers) | Compression (jaw plates) | High-speed impact |

| Best For | Fine/medium crushing | Primary crushing | Secondary crushing |

| Energy Efficiency | High | Moderate | Low |

| Dust & Noise | Low | Moderate | High |

| Wear & Tear | Low | Medium | High |

Maintenance Tips

- Inspect rollers regularly for wear.

- Lubricate bearings and moving parts.

- Adjust roller gap for consistent output.

- Clean sticky materials to prevent buildup.

- Monitor vibrations to detect issues early.

Buying Considerations

- Check material hardness and machine design suitability.

- Choose capacity based on production volume.

- Compare energy efficiency across models.

- Ensure availability of spare parts and service support.

- Balance initial cost with long-term operating expenses.

Future Trends

- IoT & smart monitoring for predictive maintenance.

- Eco-friendly designs with reduced emissions.

- Advanced wear-resistant roller materials.

- Modular designs for scalability and upgrades.

Conclusion

The double roller crusher is a durable, efficient, and versatile machine ideal for fine crushing in multiple industries. With low operating costs, energy efficiency, and easy maintenance, it remains one of the most reliable solutions for material size reduction. By choosing the right model and ensuring regular maintenance, businesses can achieve higher productivity and long-term savings.